Construction, Decks & More

Best Screws and Bolts for Docks in 2026

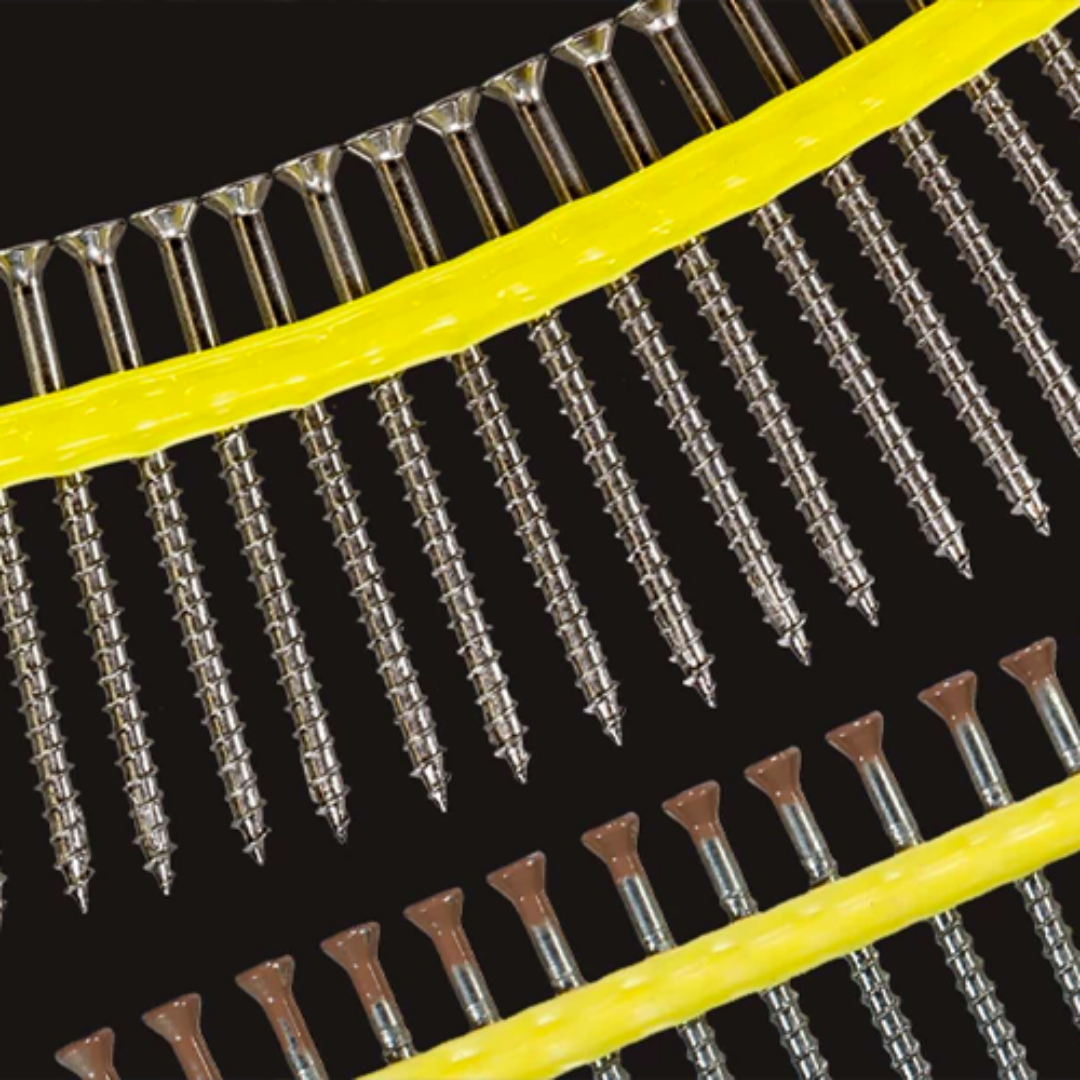

The best screws and bolts to use on a dock are stainless fasteners matched to your water: 304 stainless deck screws for inland freshwater, and 316 stainless within 5 km (3 miles) of the coast where salt spray corrodes lesser hardware fast.

Skip coated/composite screws—once that coating gets compromised, you’re inviting rust stains and fasteners that back out as the dock flexes.

For decking, use quality stainless deck screws (Eagle Claw 304/316), pre-drill near board ends, and countersink so every head lands flush (not proud, not buried). For structural and safety-critical connections, use 316 stainless through-bolts with washers and backing plates—especially for framing ties, cleats, and ladder brackets.

If you need a code-compliant lag-bolt alternative, use Simpson Strong-Drive SDS 316-grade structural connector screws where specs call for lag bolts, or Simpson Strong-Drive/SDWH Timber-Hex 316 stainless structural screws for ladder installs—paired with backing plates and tightened to spec.

For bumpers and edge trim, use 316 stainless screws with lock washers (add removable threadlocker in high-impact areas) and do a spring re-tighten after freeze-thaw. For ramps and walkways, use 316 stainless screws, leave 1/4-inch gaps between boards, and plan seasonal checks because ramps move and will loosen hardware over time.

Impact Driver History: How Builders Built Better, Faster, Pain-Free

The history of the impact driver starts way back in 1932 when pneumatic wrenches were invented, but they were stuck to compressors and air lines. Builders couldn't use them for general work—they were built for mechanics and heavy industry.

So for decades, we worked with one drill that did everything poorly. In the 1970s and 80s, Makita tried cordless tools, but those early batteries were garbage. You'd burn through them halfway through a deck. Milwaukee and DeWalt followed, but had the same problem. If you wanted real power, you needed that pneumatic compressor.

Then in 2005, Milwaukee figured out lithium-ion batteries. Game changer on the toolbelt. Suddenly you could plan a full day of work without babying your battery. But adoption was slow—contractors resisted paying extra for a tool that only drove screws.

By 2010, everything aligned. Battery prices dropped. Lithium-ion proved reliable. Contractors realized this solved problems they'd lived with forever: wrist strain, back pain, endless hours bent over. Within a few years, 80% of builders switched. The market exploded, accessories followed, and the whole industry transformed.

Top 10 Tips on Designing The Most Durable Fence (+...

To design the most durable fence, follow these ten professional tips from our 30 years of building fences inland and coastal.

Know what material you're working with—pressure-treated, vinyl, metal, composite—they all need different care. Get your posts right with the pedestal setup: dig 24-30 inches down, throw 2-4 inches of gravel at the bottom for drainage, then pour concrete on top of that and slope it 6-8 inches above ground to shed water away from the post. Skip the tar wrap around posts—it traps moisture instead of keeping it out. Use stainless steel Torx-head screws, and always put two minimum per connection point.

If you're thinking long-term, metal posts with wood boards can last 50+ years—you just swap out boards as they age instead of replacing the whole fence. Out on the Great Plains, Tornado Alley, or near the coast where wind hits hard? Design your fence so wind can pass through—shadowbox works, keep posts 6 feet apart maximum, and run diagonal bracing 7-8 feet between corners. Keep plants back 2-3 feet from your fence line, seal wood every 2-3 years, clean it once a year with a soft brush (don't pressure wash), and walk the fence line monthly when it's raining a lot to catch problems early. These practices prevent 80% of expensive repairs and extend fence life from 10 years to 25+ years.

Impact Driver vs. Drill for Deck Screws: When to Use...

If you're building a deck or fence, you've likely wondered about impact driver vs drill for deck screws. After three decades in timber construction, here's what you need to know.

Drills excel at pilot holes, countersinking, and mounting hardware—anytime accuracy matters. They offer variable speeds and prevent smaller screws from sinking too far into the wood.

Impact drivers are built differently. They push through 3-inch fasteners, secure heavy beams, and handle repetitive driving tasks without straining your wrist. The hammering mechanism does most of the work for you.

The reality is simple: both tools serve distinct purposes. Drills handle detail work, while impact drivers tackle demanding fastening jobs. This guide explains which situations call for each tool, common mistakes that slow down your project, and best impact driver for building a deck and also the best drill. We've tested these tools extensively on actual deck builds.

Best Screws To Use for a Pergola in 2026

The best screws for your pergola are Simpson structural screws and Eagle Claw deck screws. For attaching to house walls and garage ledgers, grab Simpson SDS Heavy Duty in 5-7 inch lengths that bite deep into wall studs. When you're attaching to deck joists, use Simpson SDWS long enough to punch through deck boards and grip the framing below. For attaching to concrete patios, Simpson Strong-Bolt wedge anchors lock down post bases with 3,000+ lbs of pull-out resistance. Attaching to sheds requires verifying the framing first, if it's solid timber, SDWS handles the job.

Eagle Claw stainless fasteners cover trim work and visible surfaces without leaving rust streaks, while Simpson SD Connector screws fill every hole in metal brackets to prevent pull-through. For freestanding builds, focus on SDWS for post connections and Strong-Bolt for concrete footings 24-36 inches deep.

Only use 316 stainless if your pergola is near saltwater or swimming pools. 304-grade works inland but corrodes fast in coastal zones. Match your fasteners to your surface and environment, and you won't be redoing this project when budget screws fail.

The Best Screws for Building a Shed (30 Years of...

The best screws for building a shed depend on the component and your location. After 30 years building timber structures and repairing hundreds of DIY sheds, here's what actually lasts.

For shed framing, use Simpson SDWS 3-4" structural screws. They match 16d nails for shear strength with 340% better pullout resistance. When you're putting together your shed base or laying down floor joists, those same Simpson SDWS screws at 3" to 4" lengths get the job done on most builds. Got a bigger shed sitting on 6x6 timbers? Grab the SDWH Timber-Hex 0.276" x 4" instead.

For your plywood subfloor on smaller sheds (under 120 square feet), Eagle Claw 304 stainless #10 x 2.5" won't corrode on you. If you're pulling permits, step up to Simpson SDWS 2.5" that carry the structural ratings inspectors want. Metal roofing needs pan-head screws with EPDM washers, minimum #12 gauge. Go 316 stainless if you've got treated wood up there.

Heavy doors need Simpson SDS Heavy-Duty 1/4" x 2.5" screws on the hinges. Lighter doors do fine with Eagle Claw 304 #10 x 2.5".