Construction, Decks & More

Top 6 Accessories That Make Screw Driving Easier & Faster

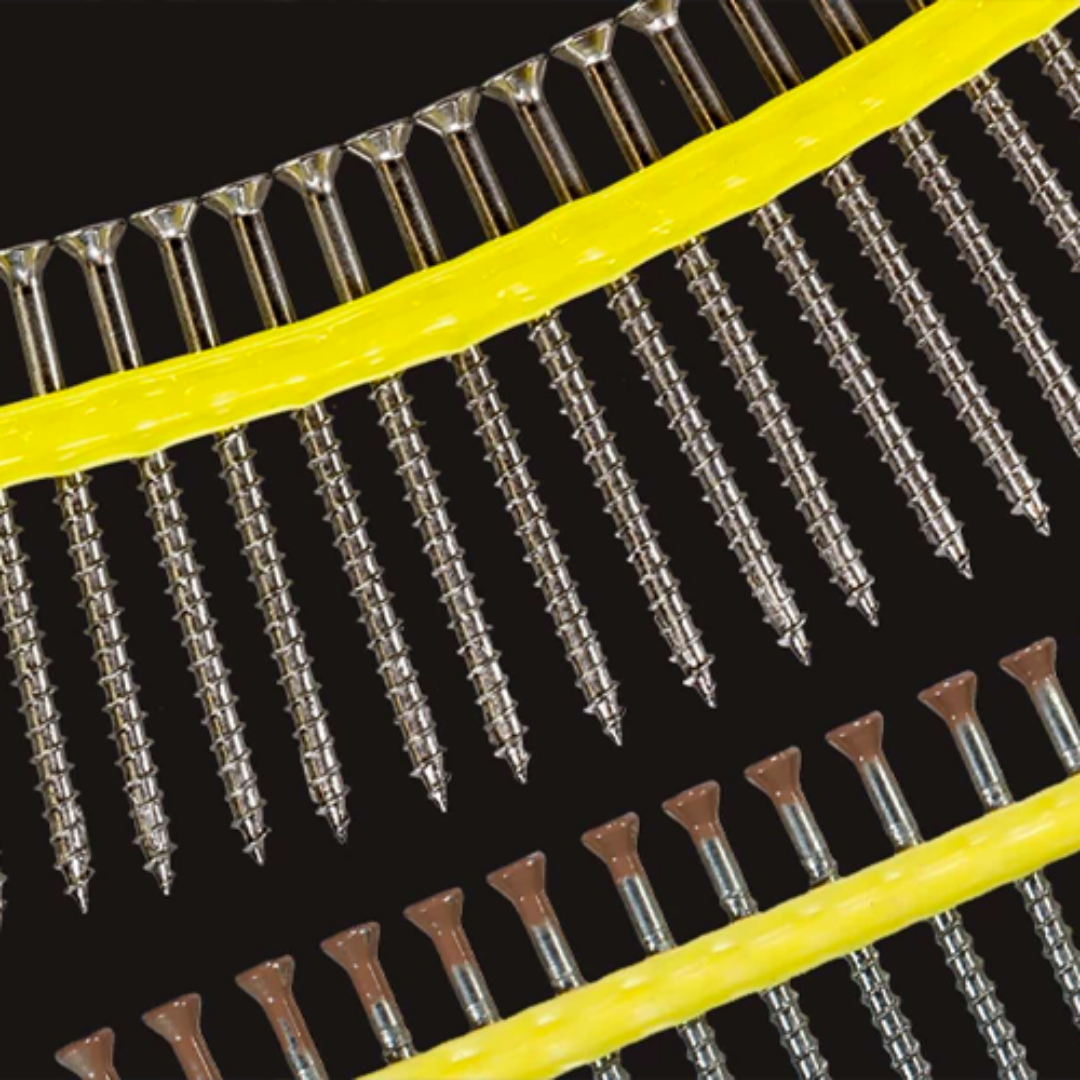

Best Screws for Pressure Treated Wood in 2026

Eagle Claw's 304 and 316 stainless steel screws and Simpson Strong-Tie's are the top screws for pressure treated lumber.

Summary: The best screws for pressure treated wood are 304 stainless, 316 stainless, and hot-dipped galvanized fasteners rated for ACQ/CA lumber. Eagle Claw 304 stainless deck screws cost way less than premium brands while delivering 40+ year performance inland.

Coastal projects need Eagle Claw 316 marine grade screws. 316’s molybdenum stops pitting corrosion from salt air. Simpson Strong-Tie SDWS structural screws replace lag bolts with ICC-ES load ratings for framing connections. Tight budgets can use Deck-Drive DSV polymer-coated screws.

Look for coarse threads that grip through moisture cycles, Type 17 points that prevent edge splits, and star drive heads that won't cam out. Skip drywall screws, electroplated zinc, and yellow dichromate. These fasteners violate IRC R317.3 and corrode within 18 months. Building inspectors require hot-dipped galvanized minimum or stainless steel in ACQ and CA treated wood.

Best Screws For Structural Timber In 2026

The best structural wood screws are Simpson Strong-Drive SDWS for deck ledgers, deck joists, docks, pergolas, retaining walls, and general timber construction. Simpson SDS Heavy Duty Connector Screws handle joist hangers, LVL beams, and multi-ply assemblies. Simpson SDWH Timber-Hex screws suit contractors who prefer hex drive. All three carry ICC-ES approval (ER-192 and ESR-2236) that inspectors accept without argument.

Regular deck screws fail code for load-bearing work. Actual structural screws need published load values like 485+ lbs shear and 790+ lbs withdrawal in Douglas Fir. Skip pilot holes entirely. Installation runs faster than lag bolts, and coatings resist treated lumber corrosion.

Marine construction needs Simpson 316 stainless steel screws because saltwater kills standard fasteners in months. When you're spanning 10+ feet on a pergola without a center support, go with SDWH timber-hex screws. Those beam-to-post joints take massive shear forces. Retaining walls facing constant soil pressure demand SDWS heavy gauge with washer heads.

Each wood structure demands specific structural wood fasteners with proper documentation.

Why Contractors Should Care About Eco-Friendly Fasteners

Wood screws can be eco-friendly if they're rust-proof and can last more than your lifetime. What matters most is using screws that won't need replacing every few years.

316-grade stainless steel screws are best for coastal salt spray and humidity without rusting, which cuts down on waste and callbacks. For inland spots with lower humidity and moderate temps, 304 stainless does the job fine and costs less.

Coated screws with ceramic or epoxy finishes last longer and use less energy to make than old-school galvanized options. There are even wooden nails from LIGNOLOC that work great for certain timber projects and break down naturally.

The best eco-friendly wood fasteners mean fewer repairs, fewer screws going into landfills, and timber structures that hold up. Brands like Simpson Strong-Tie and Eagle Claw design screws that can be easily installed and can withstand every climate for years. For contractors, this saves time and money and cuts their project’s carbon footprint.

Innovations in Fastening Technology: What's New in 2025

The new fastening technologies in 2025 include biodegradable fasteners, recycled and recyclable fasteners, coated fasteners with carbon-neutral coatings, smart fasteners with sensors, and customized, co-engineered fasteners.

There are also Simpson Strong-Tie products released in 2025, including the MPSC™ High-Capacity Connections for Mass Timber, Enhanced Mass Timber Screws, and Sage System™ Pergola Connectors.

The Right Drill Bit Size for Wood Screws to Prevent...

The size of the hole for wood screws for pilot holes should be smaller than the minor diameter (the size without the threads) of the screw for softwoods. For hardwoods, use a larger bit for pilot holes.

The size of the hole for wood screws for clearance holes should be the same size or slightly larger than the major diameter (the size with the threads) of the screw.

You can know what drill bit to use by “eyeballing” it or using a caliper. For beginners (and people with bad eyesight), the easiest way is to buy a wood screw gauge on Amazon. Just slide your bit or your screw into the slot for the type of wood you’re using, and you’re done.

Always use pilot holes for stainless steel wood screws. Always drill clearance holes when joining two pieces of hardwood.